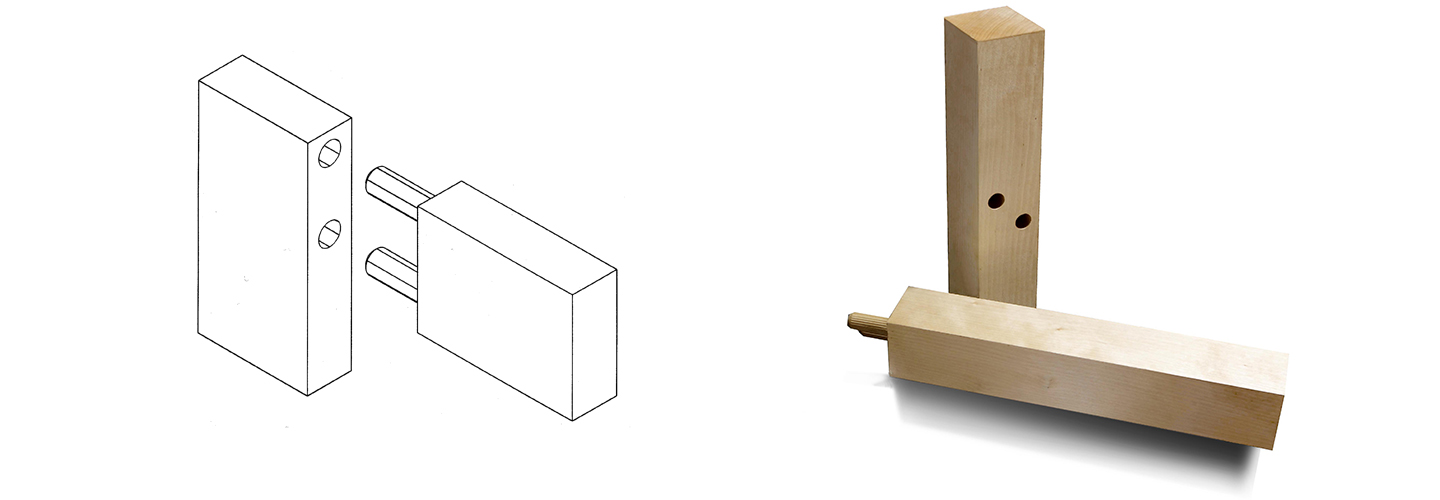

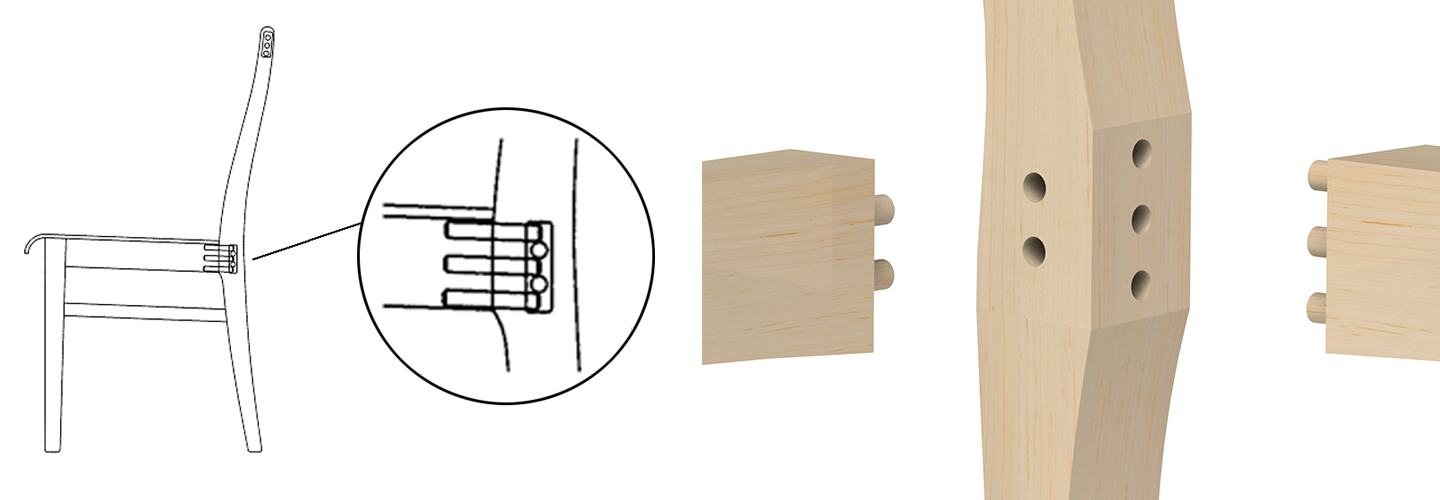

Dowel joint is nowadays used widely because it is easy to make, it does not need extra length of the work piece and it is quite strong. Usually tenon and mortise joint is stronger but if it is used in joining side rails to the back legs of a chair it can be stronger than tenon. This is because the dimensions of the leg are often restricted and tenon joint will be too short. The dowels can be located by turns and in that way can be made longer and stronger.

The strength of a dowel increases when the dowel gets longer so it is always profitable to make the dowel long. The strength grows also with longer dowels when the dowel is against the grain direction and when breaking happens because of cleavage of the piece on the left in picture 1. There is however limit to the length of the dowel because it breaks if the mortise piece don’t break first.

The joint structure usually causes loads which tries to pull the dowel out of wood. This makes the shear strength of the dowel important. To maximize the shear strength the dowel must have good contact with the wood and the glue spread must be even. The surface of the dowel is grooved. This allows the glue on the bottom of the hole to spread on the surface of the dowel when the dowel is pushed into the hole.

Presupposition to this is that the depth of the hole is precise about 1 mm deeper than the length of the dowel. The amount of glue must be precise. If there is too little glue it cannot spread on the whole surface. If there is too much glue it gets out of the hole and it will make the assembly of the component more difficult or it can make dirty the surface of the component which spoils the visual quality of the component. If the hole is made with little chamfering there will be little space for glue getting out. The glue must have low viscosity to be able to spread when the dowel is pushed in. If the viscosity is high and pushing happens very fast the work piece can cleave.

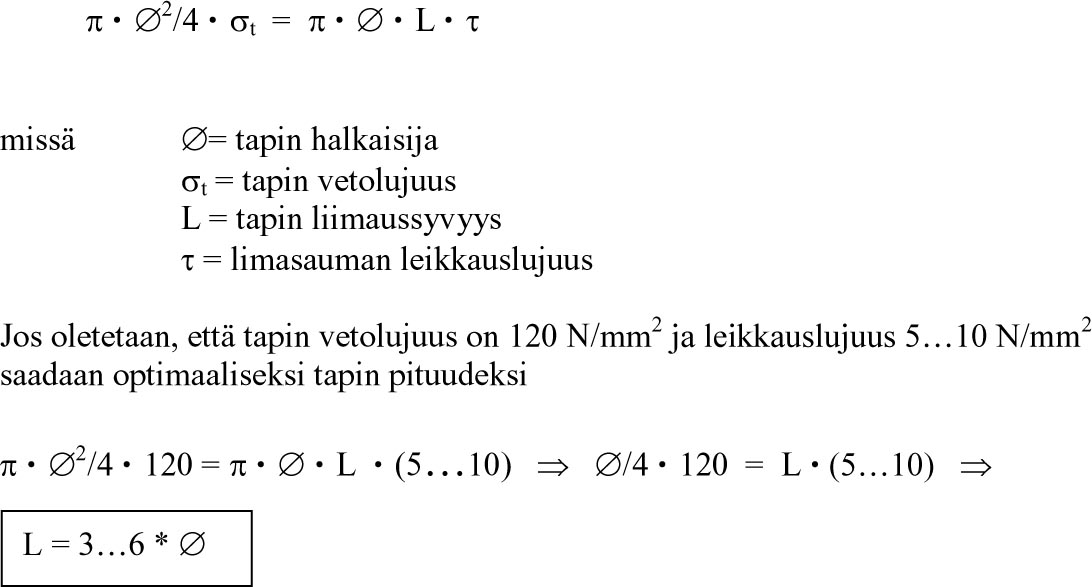

The strength of the joint can be increased by making the glue surface larger with bigger diameter or longer dowel or by using more dowels. If the dowel is very long the load caused by the shear strength may be bigger than the tension capacity of the dowel and it will break. One way to optimize the length and diameter of the dowel is to make the following equation:

tension load = shear load

So if we make the glue length of the dowel 3…6 times the diameter of the dowel the strength properties of the dowel are used optimally. If the dowel is against the grain direction it can be up to 20 ·Æ long depending on the cleavage strength of wood.

The diameter of the dowel

The diameter should not exceed half of the thickness of the component.

The surface profile of the dowel

The strongest dowel joint is achieved with smooth dowel surface. This happens only if glue can be spread all over the surface. When the tolerance of the dowel is tight the glue can’t spread or it is wiped off creating a weak joint. That’s why dowel surfaces are always grooved. Grooves can be made by embossing or moulding. Embossing is better if we think about the strength. When water based glue is used grooves let the glue spread and the moisture makes the grooves swell back making a nearly smooth surface.

Moulding is however an easier way to manufacture dowels and nowadays they are made in that way. Grooves cannot swell with moisture and the joint is a little bit weaker. Because gluing doesn’t need as good accuracy as with smooth dowels it is possible to get stronger joints in practise.

Grain direction

The joint is strongest in the grain direction. However grain direction doesn’t affect the strength much. This is good because the designer doesn’t have to think about the direction of the joint.

The length of the dowel

The strength of the joint increases when the length increases, so, the dowel should be as long as possible. However, deep holes are not easy to glue. So when designing the joint one can use the equation above p = (3…12) × Æ.

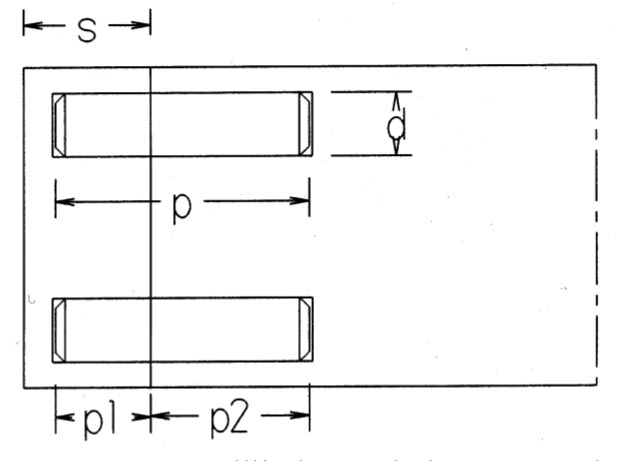

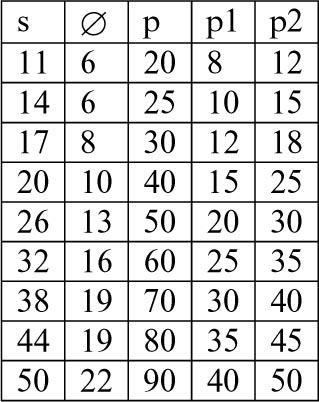

If the dowel joint is in the corner of the structure one cannot often use the full length of the dowel. In that case one can use the following table 1. See also picture 2.

Picture 2. Parameters of dowel joint

Table 1. Design parameters of dowel joints

The depth of the hole

It is very important to make the depth of the hole very accurately especially when the production is automated. When the assembly is automated there will be a certain amount of glue injected to the bottom of the hole. When the dowel is pushed in it will force the glue to flow outwards covering the surface of the hole and dowel. If the hole is too deep the dowel can’t make the glue flow enough and spread on the surface of the hole and the strength of the joint will be low.

Normally the hole should be drilled 1 mm deeper than the dowel. This tolerance allows also some length differences of the dowel.

Tolerances

The tolerance between dowel and hole must be according to the materials used. If we use grooved dowels the hole should be 0…0,15 mm bigger than the dowel.

Machining

Dowel holes can be machined with multispindle boring machine or NC-router. If there are many dowels in one joint boring must be made very accurately otherwise assembly forces grow very high. Boring usually gives clean surfaces which are easy to glue.

Normally design and machinery is based on 32 mm boring distance but other distances are used if there is not much space in the joint and if there is nc-router or special boring components available.

Benefits and disadvantages of dowel joints

Benefits

- Saves raw material the length of the tenon

- Machining is easy and fast

- Strong joint if designed properly

- Joint is clean and invisible

- Easy to automate both machining and assembly

Disadvantages

- Too much glue can split weak board like chipboard

- Low machining tolerances can make assembly hard

If for instance a frame with outer dimensions 400×400 mm is made of 50 mm broad wood dowel joint can save 50 mm frame material in each corner which is 200 mm per frame. This means 14% material save.