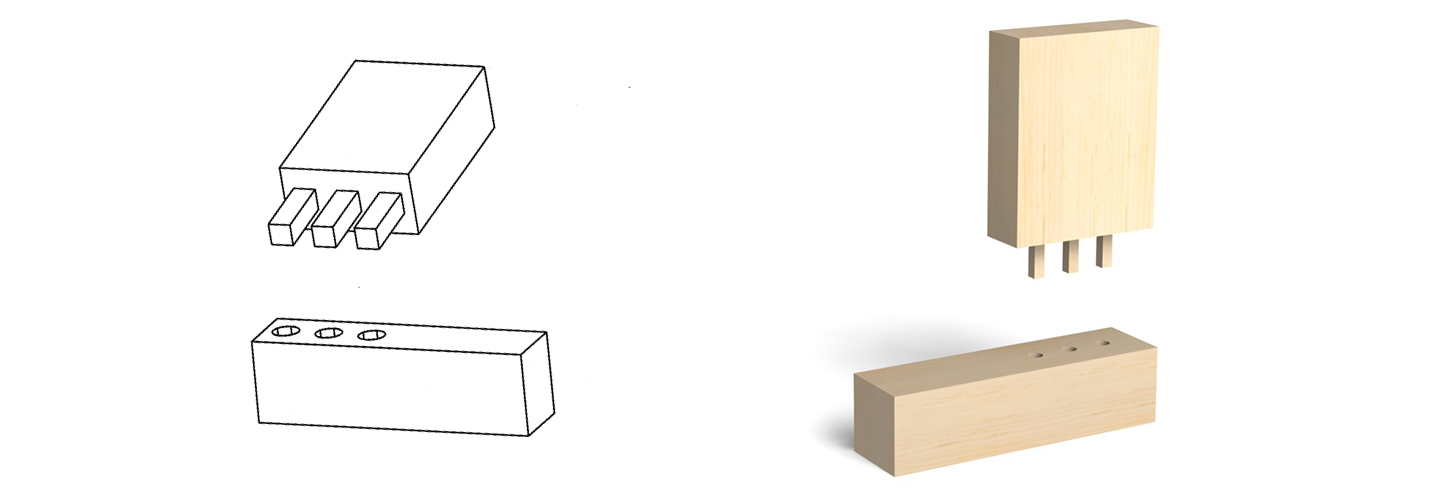

The idea of the Zabo joint is to make a joint which has the same strength as the mortise and tenon joint but is easier to manufacture. The tenon part consists of several tenons with a square cross-section. They are made in one or two rows, depending on the thickness of the workpiece. The manufacturing method is in principle the same as in a mortise and tenon joint, except that the tool set consists of more tools. The manufacture requires two work stages.

Zabo joint with rectangular tenons and round holes

Zabo joint design

The speciality of the joint is in the holes, which are not square but round. In this way they are easy to make by boring. It is important to have the right size of holes. If the size of the tenons is 10 mm, the holes are made with a 9.5 mm bore bit. When the joint is pressed together, the tenons are forced to compress and form a gluing surface.

You must be careful in the manufacture, because the joint consists of several parts, otherwise the assembly can be difficult. Therefore it is best to bore the holes with an NC machine with one attachment in order to ensure dimensional accuracy. Another factor which is important for the quality is to avoid tearing in machining the tenons. An NC-controlled machine is good for this stage, too, because it makes it easy to machine so that the tools cut on all sides towards the wood. When using a manual router, stops help, but they tend to wear, which causes increased tearing.

The strength of a Zabo joint is in the same range as the strength of a mortise and tenon joint.