The aim of drying is to prevent unseasoned wood from rotting and to dry the wood to meet the moisture requirements of its application. The drying takes 1,5 – 6 months outdoors and 2-12 days in a dry kiln. Special drying methods can shorten the drying process down to a few hours. The duration of artificial drying depends on various circumstances, such as the drying method, tree species, the size of the sawn timber, and the starting and the goal moisture content. The tensile properties of wood can be improved and the measure changes made smaller with the right kind of drying.

The biggest problem from the point of view of wood drying is shrinkage. It starts when wood dries below the saturated moisture content of the grains. The shrinkage and swelling of wood caused by moisture changes is called anisotropy. Shrinkage depends on the different structures of the wood. Shrinkage along the grain is slight. Tangential shrinkage is the most intensive shrinkage, and the amount of radial shrinkage is approximately half of the amount of tangential shrinkage. These differences result from the different physical properties of wood along the radius, tangent and lengthwise direction.

Generally known drying theory

When drying a porous and solid piece of wood, the water from the inner parts should be made to move towards the surface of the wood and further into the surrounding air.

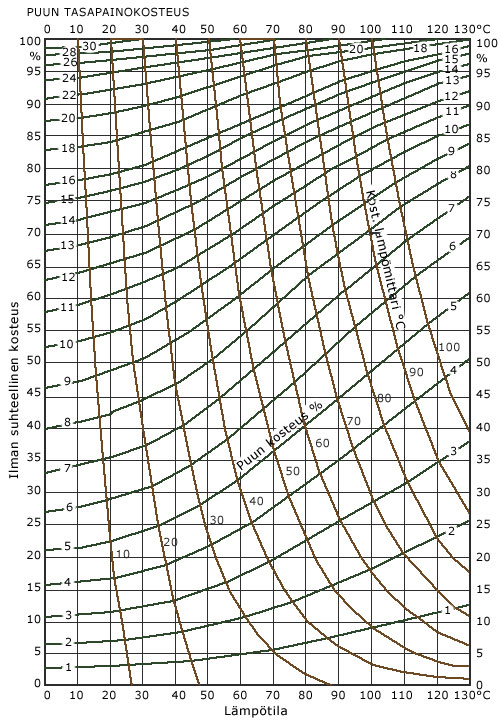

Wood is hygroscopic, i.e. water absorbing, matter which absorbs water vapor from the air. Wood reaches the equilibrium moisture content in a room where the temperature and humidity are stable. In other words, the amount of absorbing water vapor is as large as the amount of outgoing water vapor. There are many factors affecting the time in which the wood reaches the equilibrium moisture content. An ideal situation in the final phase of drying wood would be that the conditions of the dry kiln would be equal to a space where the wood would reach the equilibrium moisture content set for it.

Moisture appears in many different states in wood. Water appears in the lumens as the wood’s moisture content exceeds the saturated moisture content of the grain. This water is called capillary water. The moisture content of a saturated cell wall is approximately 30% when the temperature is 20ºC. When the moisture content is below the saturated moisture content of the grain, there is water only in the cell walls. This water is called bound water. In addition, there may be water vapor in the form of humid air in the lumens and pores. All the three states have their own shifter mechanisms, which should be taken into account in the theory of drying wood. In the winter, moisture can also appear in the form of ice. Melting icy wood should be taken into account in the drying process, as it is done as a separate phase before the actual drying.

Straight after felling or otherwise very moist wood contains water in every three states. The drying process starts with the evaporation of water. The free water in the lumens moves according to the capillary action from cell to cell towards the surface of the wood. According to the classical theory of drying, free water evaporates from the surface of unseasoned wood at the same speed as water evaporates from an open fluid surface. Not until all the free water has evaporated does the bound water start leaving the cell walls. The bound water in the cell walls is adhered to microfibrils partly physically and partly chemically. The less there is water left in the wood, the more it requires energy to remove the water from the wood. This is caused by the fact that the water molecules leaving at the final stage are attached to free OH groups.

Bound water has three different ways of moving inside wood:

- From the cell wall the water evaporates into the lumen, from which it passes into another cell via bordered pits.

- From the cell wall the water evaporates into the lumen, from which it adheres to the other wall of the cell, from which it diffuses.

- The water moves along the cell walls.

Water moves in all these three ways at the same time. The significance of how the water moves depends on the moisture, the apparent density and the temperature. Main part of the water moves by diffusion via the cell walls. As the drying continues, the water starts to evaporate slower, and the water vapor in the wood starts to escape until the wood reaches the equilibrium moisture content. Reaching the equilibrium moisture content means that the amount of the water molecules on the surface is fixed, in other words, the moisture of the wood becomes balanced with the humidity of the surrounding air.

Drying methods

- Air drying

- Warm-temperature drying

- Chamber drying

- Canal drying

Special drying methods

- High-temperature drying

- Condensation drying

- Vacuum drying

- High-frequency and microwave drying

- High-frequency negative pressure drying

Spruce is easier to dry than pine. Therefore the drying costs of spruce remain smaller than those of pine. Birch, on the other hand, is even more difficult to dry than pine, because the duration of the drying of birch is considerably longer and birch wood is susceptible to changes in colour.