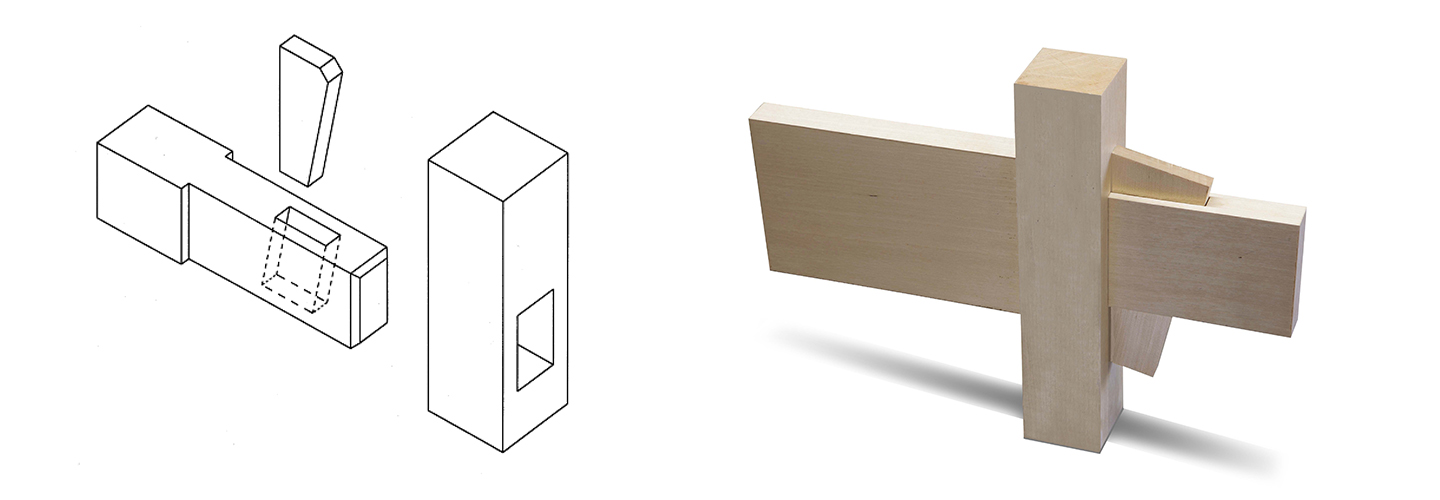

The wedge joint is a traditional visible joint in cases when opening must be possible. It is easy to tighten again. The manufacture of the joint requires many work phases, and for this reason it is not used much. When the joint is assembled, a wedge is pushed into the hole of the mortise piece. The hole must have the same inclination as the wedge. The wedge angle must be under 20 o so that the wedge will stay tight.

Wedge joint design

The joint is quite complicated to manufacture and it extends a long way through the jointed piece, which possibly hinders the use of the product. Easy opening and tightening ability are the good sides of this joint.

The strength of a wedge joint

When the wedge is pushed into the joint, it causes shear force to the mortise piece. Because the shear strength of wood is small, the area under shear stress must be dimensioned large enough. When dimensioning the joint, you can use the following model. The idea is to define the shear force of the mortise piece equal to or preferably larger than the compression force of the wedge.

2 • a • b • τ = t • b • sp

Where

a = the distance of the wedge from the end of the mortise piece

b = height of the mortise piece

t = thickness of the wedge

τ = shear strength of wood

sp =compression strength of wood against grains

For instance if t = 10 mm, sp = 5 N/mm2 and τ = 1 N/mm2, we get

![]()

The mortise must be made 25 mm from the end of the mortise piece.

Characteristics of wedge joint

Benefits

- Easy to open and tighten

- Decorative

Disadvantages

- Complicated manufacture

- Needs space