In a doweled joint, the dowel together with a bolt receives the shear forces. Dowels are divided into two main groups depending on whether the dowel is placed in a slot or groove made in wood or whether the dowel is forced into the wood. A bolt is usually used in connection with dowels as a separate connector. Traditional and simple dowels include a pin placed in a hole, and a rectangular dowel, which requires a hole of the same size.

A dowel bar is a straight, smooth or grooved steel rod with a typical thickness of 8 to 30 mm.

The making of groove dowels calls for a special tool, with which a groove ring required by the dowel is milled in the wood by utilising the bolt hole that comes to the centre of the dowel. The most typical groove dowels are of a ring or plate type.

Rectangular dowels are traditionally of a hard wood. By means of a steel dowel used nowadays, a rigid shear connection between the steel rod and wood can be made by welding.

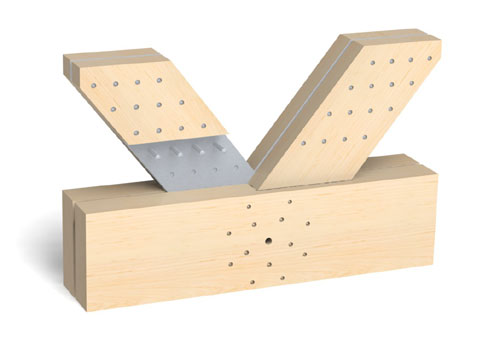

Tooth dowels are connectors punched from steel plate 1 to 1.5 mm thick and pressed into wood. These dowels have triangular teeth bent rectangularly against the plane of the plate. Dowels with teeth on two sides are used when wood is connected to wood, and dowels with teeth on one side are used when wood is connected to concrete or steel. The increased use of glued laminated timber recently and components such as nailing plates have reduced the use of doweled joints.

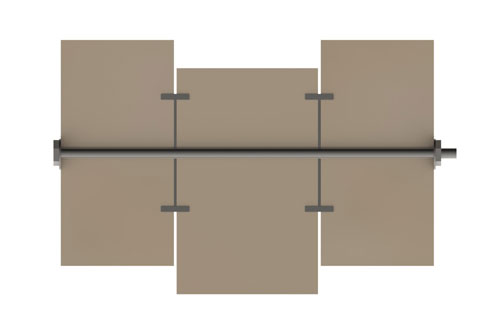

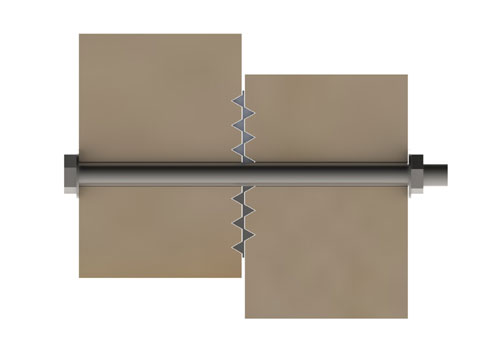

In nailing plate joints, metal plates are inserted in grooves sawn in wood. The holes required by the pins can be made using various methods. If the connecting plates are thin (2 mm), the nails do not need pre-drilling, because they penetrate both the wood and 3 to 5 plates placed in parallel grooves (Greim method). When the dimensions of wood are more robust and the metal plates need to be thick, the nails need pre-drilling.

Greim joint