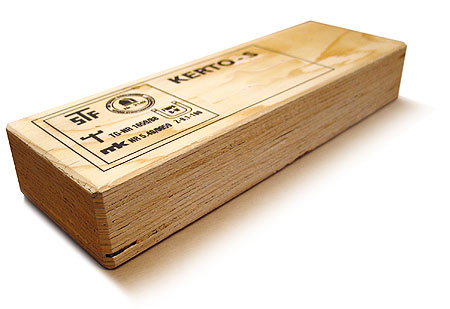

Laminated Veneer Lumber (LVL) is manufactured by gluing together veneer sheets that are about 3mm thick. It is also manufactured in Finland. Kerto® and Kertopuu® are Finnish LVL brands.

LVL is good for constructing long beams or very large sheets. LVL is thicker than plywood and thus the strength of the material, especially in long beams, is excellent. The glue used in LVL is weather proof phenol resin. The material used to make LVL is usually spruce and that’s why there are usually signs of branches on the surface of LVL.

LVL is also made for AB-qualifications for pressure saturation. LVL qualified as AB, is suitable for construction that has to endure weather. It is not suitable for constructs touching water or ground. Neither is it suitable for safety constructs.

Usage of LVL

- supporting the base of a roof (Kerto-S)

- hull beams in walls (Kerto-T)

- stiffening sheets in roofs, walls or floors (Kerto-Q)

LVL is also used a lot in public construction and for industrial components.

Qualities

- The structure of LVL makes it light, yet very strong. Thus it’s ideal for beams of large colume. Compared to regular lumber you can achieve way better load capacity with way less material.

- The density of LVL is ~480 kg//m3 (in about 10% moisture). The pollution class is the best possible, M1.

LVL Products

- Beams, where all of the veneers are aligned lenghtwise. Veneers are combined with strong angled joints into layers and then glued together. Afterwards the product is milled into beams

- Sheets where some of the veneers are aligned by fiber and some are perpendicular.