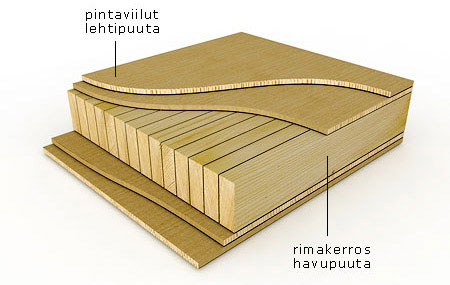

Lamin board consists of 3 or 5 layers where the middle layer is thick layer made from thin (under 7mm) splinters. Surrounding the lamin layer there are one or two thin veneer layers made of deciduous wood. Laminated splinters are glued together from deciduos veneer, like plywood, and then cut to thin slices. Lamin boards are not very common these days as the manufacturing of chipboard has taken over.

In Finland there was batten board and lamin board manufacurers in 1940’s. Nowadays foreign lamin boards and batten sheets the veneer might be made of beech, alder or cottonwood.

Qualities and usage

- Lamin board is used in places where you need to tough material to hold up weight, such as shelves.

- Due to structure of the lamin sheet you get a lot of waste pieces.

- Lamin sheet is easy to work with. It is however much more expensive than chip board.

- If the batten used in the core is distorted, there might be holes inside the sheet. These holes don’t have a big impact on the stength of the sheet but they can make attaching screws and such more difficult.

- The veneer surface might crack in time and make cracks in the polish or paint.