Veneer is thin board that is sawn, sliced or lathed from wood. Generally veneers are 0,6 – 4 mm thick. Veneers are produced from both domestic tree species and rare tropical species. There are also technical or artificial veneers, which are produced by dying and gluing together wood material.

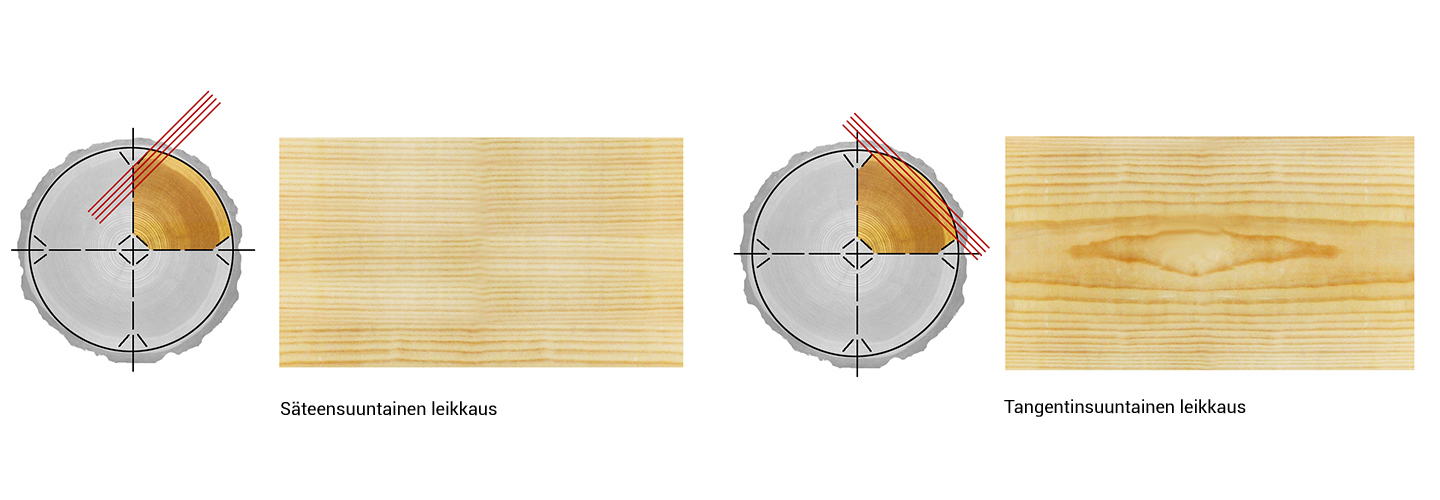

The raw material, however, has to be of good quality. Industrial veneer is produced by lathing or slicing. Generally the cheapest tree species are lathed and the more valuable ones are sliced for veneer that is used for more demanding purposes. The production method affects the surface finishing properties and the appearance of the grain pattern. Carpenters can also produce separate veneer surfaces by sawing.

Veneering can bring out the uniqueness, exceptional colours and twisting patterns of wood fibres.

Genuine veneers

- Genuine veneers are lathed or sliced from round logs

- It is possible to utilize wood effectively by producing it into veneer. One cubic metre of wood usually provides approximately 250-1000m2 of thin veneer.

- Using valuable tree species as large veneer surfaces is ecologically and economically rational.

Technical veneers

- Technical veneer is produced from common tree species (for example aspen) that are cultivated mainly for the carpentry industry.

- Technical veneer is produced from thin-lathed veneers, which are discoloured or dyed throughout. In order for the production to be effective, the treated veneers are glued together to form a log as large as possible. Thin, technical veneers are cut from the log in cross direction with the gluing.

- The veneers become uniform in quality, their patterns and variations in colour are controlled. Technical veneer production provides nearly endless possibilities to create different types of veneers.

- Throughout dyed veneer can be polished without changing the appearance of the surface.

- Producing technical veneer is a lesser burden to nature, because cultivated wood can be used as raw material and the amount of production waste is notably smaller than the one of ordinary veneer.

- Very thin 0,3 mm veneers are called micro veneers. Paper is used on the rear side of micro veneer. The use of micro veneer in furniture and construction industries has been minor.

- 3D veneer is technical veneer, in which lathed veneers are sawn into strips, after which the strips are turned and tied together again. The final result is veneer that can be shaped into tricky, even ball-shaped, shapes and several directions.