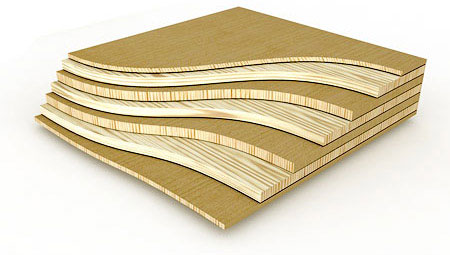

Finland is the EU’s biggest plywood manufacturer. The main ingredient of domestic plywood is fir and birch. Turned veneer is glued by cross graining each layer. These plywoods are made in 3 categories, fir plywood, birch plywood and mixed wood plywood. The gross grain gluing prevents from the board changing its shape when the surrounding air moisture changes.

Phenol formaldehyde resin is commonly used as glue. It can withstand rough conditions. This is why the edges of the plywood look red. Colorless glue can be used in situations where the glue is not wanted to be shown. This kind of plywood is more expensive but can’t withstand tough conditions.

Out of all the boars, plywood is the best and toughest board. onkin puulevyistä tässä suhteessa kestävin (EN-314-2:luokka 3 exterior). The strength properties and the wood like appearance gives the plywood many purposes of use. These can be building, used as a concrete mold, decorating and also for transportation purposes.

Plywood types

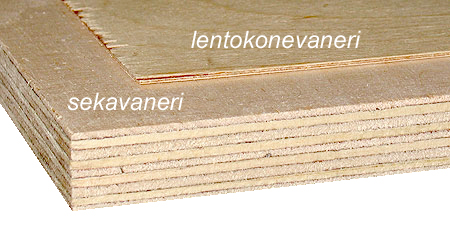

There are 3 types of plywood boards made in Finland. Fir plywood, birch plywood and mixed wood plywood, this plywood is cheaper than birch plywood but are a little weaker than birch plywood

Birch plywood

- Toughest and most expensive plywood..

- Veneer layers are thin (1,4 mm)

- The top layer of veneer determines the quality of the plywood board.

- A Flawless special plywood (supply of veneer is limited)

- B Varnishable surfaces

- S Paintable surfaces

- BB Normal quality, regularly used at construction sites as protection

- WG Suitable for less demanding situations

Measures for built birch plywood boards

1200×1200/2400/2500/3000/3600 mm

1220×1220/2440/2500/3050/3660 mm

1250×1250/2500 mm

1500×1500/2400/2500/3000/3600 mm

1525×1525//2440/2500/3050/3660 mm

1525×1525//2440/2500/3050/3660 mm

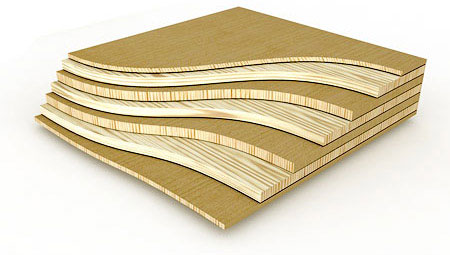

Mixed plywood

- The 2 outer layers of veneers are birch.

- Veneer in the middle is both birch and fir. Fir veneer is either as thick as the birch veneer, or bigger.

- Flexibility of the board is good both ways.The quality and measures of the top veneer layers are the same as in birch veneer.

Mirrored mixed plywood

The veneer in the surface is birch, the middle layers fir and birch. This way the grains of the birch layers go the same way and all the fir layers are gross grained. Flexibility varies a lot depending on the direction of flexing.

Twin plywood

- Only the surface veneers are birch.

- The surface is tougher and the appearance is more even than in coniferous plywood.

- The lightness of the board can come in handy at times.

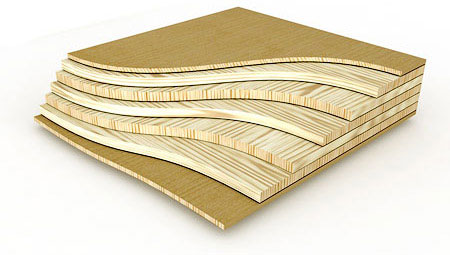

Conifer plywood

- Weaker and lighter than birch plywood.

- The toughness of a early fir wood veneer and summer fir wood veneer varies quite a lot.

- Turned fir veneer is usually about 2mm – 3,5mm.

- A top layer with no branches is achieved by turning a quality pine.

- Qualities of the surface veneer on a coniferous plywood:I Nearly flawless quality, only with a pinewood top layer. Limited supply.

II Intact surface

III Veneer isn’t patched, suitable for constructionThe grain direction is normally the same direction as the long side of the board when on a birch plywood its the opposite way.

Measurements of the coniferous plywood: 2440×1220 mm, 2500×1250 mm

Usage: Spruce plywood is mainly used in construction. Pineveneer plywood is used in interior design and other applications that require good appearance.

Thin veneer plywood or aeroplane plywood

- Made from very thin veneer to be a specialty product.

- Benefits: Tough and flexible.

- Thickness is usually 0.4 – 1.2 mm, but there are some boards that are thicker.

- Usage: for example miniature models and design-wood products.

Coatings

Different coatings are made for different uses. The quality, durability weather proofing can be improved by coating plywood. Coated plywood has a protective color layer on the edges of the board.

- Smooth or friction film coating

- Laminated coat

- Rolled or painting surface film

- Painted or varnished coat

The most common coating is film coating. The film coat is made by hot-pressing a film on the wood. The resin of the wood hardens when heated and eventually hardens in to a plastic coat. The base material of the film is usually paper but can sometimes be glass fiber.

Some of the coatings are meant for technical uses. Some of them are suited for both outdoors and indoors. And they withstand UV-radiation and other stress. The coating meant for technical uses can be discolored by the radiation.

Friction surface is made by a pattern on the plywood during the hot-pressing process. Friction surfaced boards are used in various transportation situations.

Properties

Good properties

- Tough compared to its weight.

- Disfiguration by moisture is minimized

- The glue seam can withstand tough conditions.

- Doesn’t crack like sawed material.

- Good qualities of the wood are preserved.

- The glue used in plywood doesn’t cause harmful emissions

Problems

- Thinnest plywood might bend.

- The sizes of the board depend on the rounded veneer.

- The actual thickness of the plywood can vary compared to the written thickness.

- Birch plywood is expensive compared to for example chipboard.

Big changes in moisture can crack the top veneer layers.