The rebate joint is usually used as a corner joint. Because rebate joint in itself is quite weak, it is usually strengthened with nails, screws or staples. These strengtheners also bind the joint while the glue is hardening. It is also possible to use dowels as strengtheners if the dimensions of the joint allow that. If special strength is required of the joint, strengthening nails etc. can be nailed from two directions. It is reasonable to drill holes for screws and thick nails because they must be located very near the end of the piece.

The rebate joint is easy to manufacture. For instance with a tenoning machine it can be combined with other machining operations. In window frames it is replacing the traditional slot joint because cutting the rebate can be combined with cross cutting. In this way it is possible to avoid investments in expensive tenoning machines.

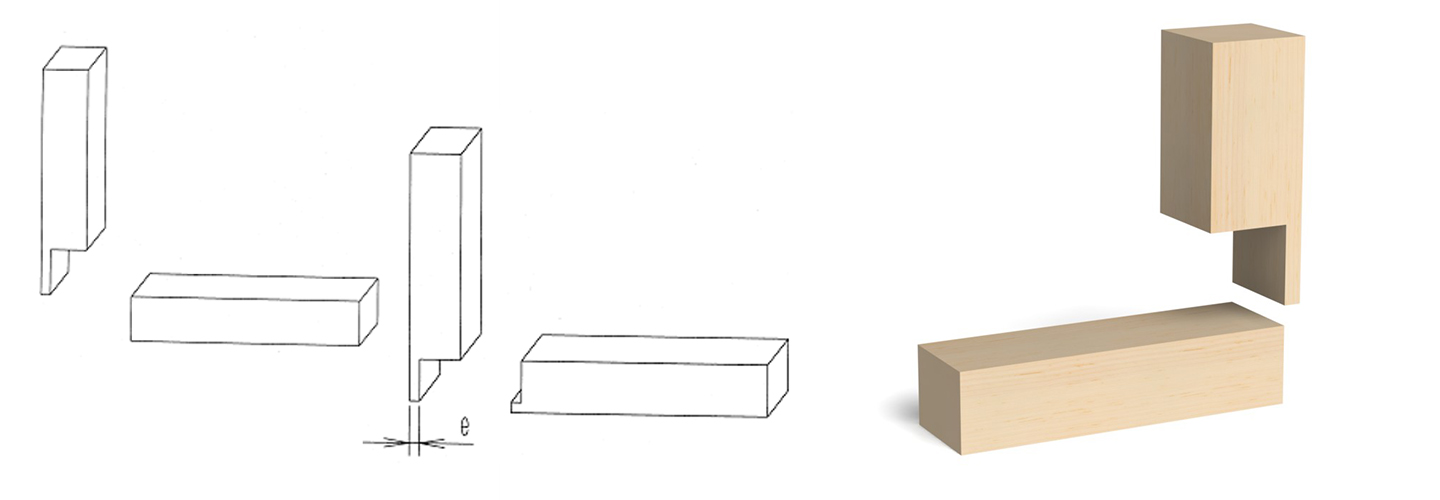

Rebate joint can be made with only one or both pieces cut.

Design

The rebate must always be cut as deep as possible in order to get the best strength. The edge of the rebate (e) will then be thin, about 3-5 mm is a suitable thickness. The width of the rebate can also be reduced by cutting (picture 1. on the right) if the objective is to hide it.

Benefits and disadvantages

Benefits

- Easy to make, can be combined to another work phase

- Nearly invisible

Disadvantages

- Weak joint

- Needs nails or screws to be strong