The dovetail joint is used in corner joints. It is a very decorative joint, which locks itself. It is a little difficult to manufacture but with proper machines there is no problem.

Dovetails are usually made with even spacing but it is also possible to vary the spacing. The joint can be made visible on both pieces or only on one piece, or it can even be made invisible. Usually it is visible, because of its decorative effect.

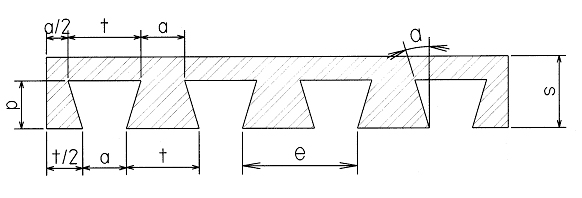

Design parameters

The joint is machined with conical tools, so the cutting depth affects the geometry of the joint.

The joint gets stronger when the tenon gets longer. When it is made half visible the length (p) of the tenon is often ¾ of the thickness (s) of the mortise piece.

From picture it is possible to get the following equations

With the equation above it is possible to calculate the parameters of dovetail joints.

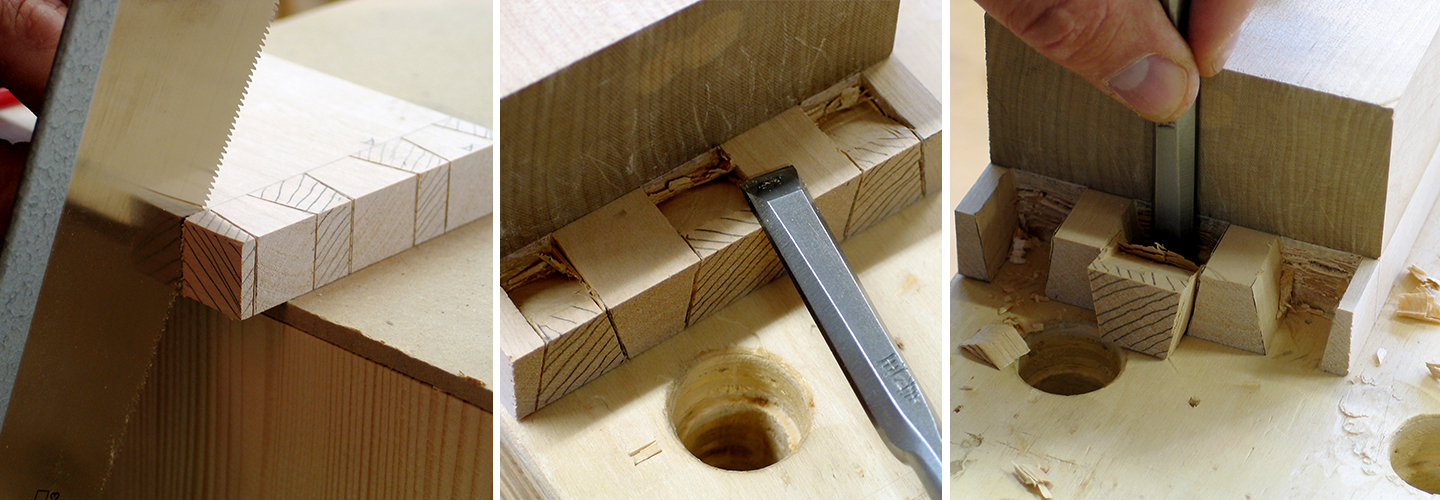

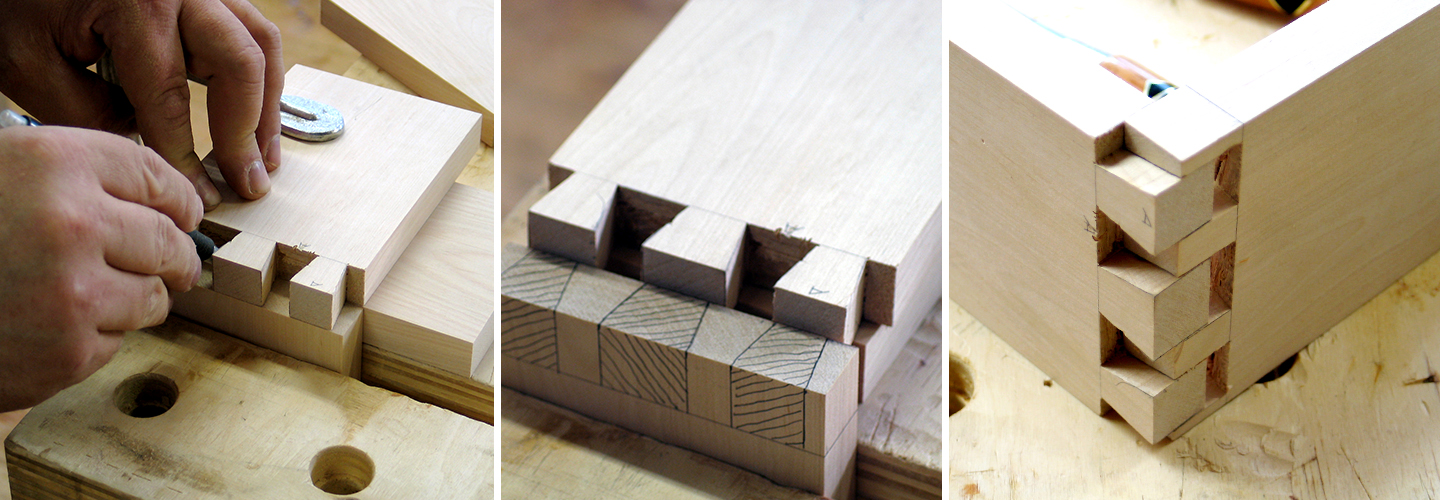

Machining

Dovetail joints have been made with special dovetail joint machines. When it is made with machines, the joint is designed as the right joint in picture 1.Small numbers can also be made with hand routers and suitable jigs. Then it is possible to design the joint like the left joint in picture 1. The best way nowadays is to make them with NC routers. An NC router has good accuracy and the joint will be clean. The traditional way to make them is to cut both parts of the joint at the same time. The components are placed in the router one piece horizontally and the other vertically. In this way the mortises and tenons fit together and working is efficient.

Use of the dovetail joint

The dovetail joint is mostly used in drawers. It is a good joint for front rails because it locks itself and it will stand pulling of the drawer even if the glue joint had broken.