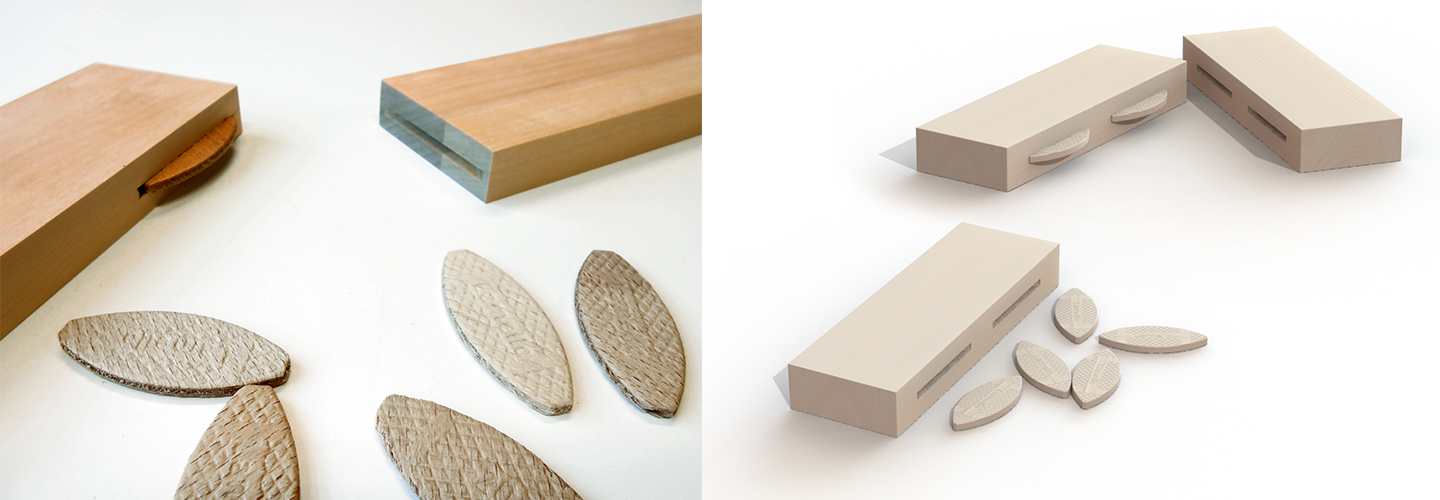

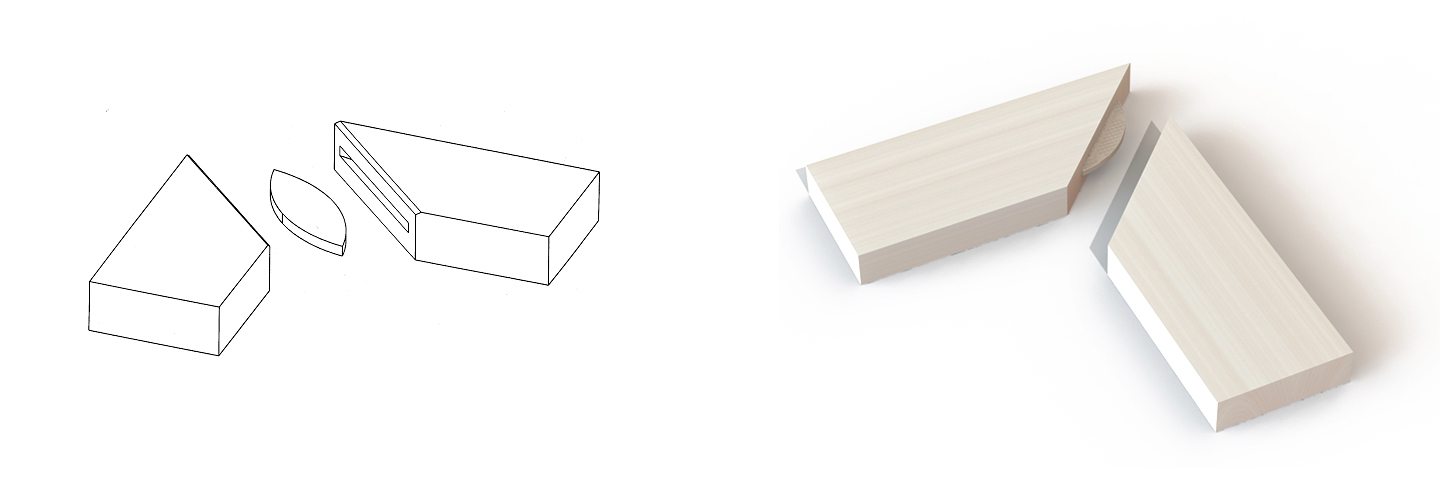

The lamello joint is based on the force of an oval piece (called biscuit) glued into slots in both pieces to be jointed. It is used in the assembly of cabinets, frames etc. to replace a dowel joint. Its advantage is that it can be made with manual tools with a very short setup time and it does not need very exact positioning. If a dowel joint is made with a traditional multi-spindle drilling machine, the setup takes quite a long time. As a working stage, making a lamello joint is slower than making a dowel joint with a multi-spindle drilling machine. Therefore it is best suited to situations when the serial size is under five.

Biscuits are also more expensive than dowels. The biscuit lengths available are 47, 56 and 85mm and they are made of beech plywood, aluminium or plastic.

Dimensioning

There are no exact dimensioning rules for the lamello joint. In corner joints the biscuit is placed in the middle of the board and the number of biscuits is based on experience. As some kind of rough dimensioning rule you can say that in the compression and tensile bending of the corner joints of 16mm thick pieces the strength of one 56mm long lamello is roughly equivalent to two 8mm dowels. In straight tension one lamello is roughly equal to one dowel. As a general rule of thumb you can say that one lamello is equal to two dowels.

Benefits and disadvantages

Benefits

- Fast with short series

- Invisible

- Quite strong joint

- Does not need accurate dimensioning of the joint

Disadvantages

- A little expensive bits

- Slow with long series