The durability of gluing is affected by the structure and moisture content of the wood, shrinkage and swelling caused by changes in humidity, the quality of the surface to be glued, density, resin and oil content, and differences between the properties of different parts of the trunk.

Wood structure

Wood has an anisotropic structure, which means that its properties are different in different directions. Wood has three directions; radial and tangential cross-sections, and perpendicular cross section against the grain. In practice, the glue surface is a combination of two or even three cutting directions.

Gluing is most difficult along the grain because the contact surface is small. It is a disadvantage if a large amount of glue is absorbed by the lumen, because then too little glue easily remains in the joint. In addition, the treatment often breaks the cross-sectional surface along the grain, in which case the strength of the wood weakens.

When gluing joint boards, the grain has to be taken into account in the assembly. The significance of the assembly becomes emphasized when gluing slabs whose flats are tangential.

Branches, slope of grain, and other wood defects affect gluing. The absorption and adhesion is weaker on defective parts. In addition, the way the wood shrinks and swells on these parts is different compared to the surrounding wood. Tensions possibly breaking the joint may occur in the glue joint.

Resin and other extracts from wood may hinder the absorbtion of glue and reduce adhesion. The extracts from the heartwood block the wood‘s pores, which reduces the absorption of glue. The extracts from the sapwood are more liquid, and, therefore, spread easily on a worked surface and hinder the adhesion of the glue. In some cases the acidity of wood hinders gluing. Acid extracts may cause colour defects together with some alkaline glues.

The proportions of springwood and summerwood affect the durability of the joint, too. The summerwood of coniferous trees is notably more durable than their springwood. The glue absorbs more easily into the porous springwood, and, thus, the glue joint may easily remain as weak as the springwood.

Moisture content of wood

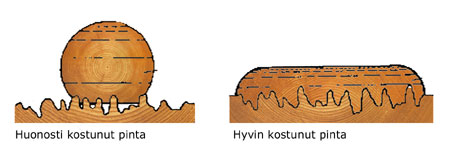

For the gluing to succeed, the moisture content of the wood should be 5-15 % in order for the wood to absorb the glue sufficiently without moistening the surface of the wood. Too moist wood, on the other hand, absorbs too much glue so that there will not be enough glue in the joint.

Wood is hygroscopic material; it absorbs or gives out moisture and sets to a certain equilibrium moisture content according to the surrounding conditions. A change in the moisture content causes the wood to swell and shrink, which causes tensions in the glue joint. Wood swells and shrinks the most tangentially and the least along the grain. Therefore, when gluing, the moisture content of the wood should be equivalent to the operating conditions. Glue also increases the moisture content of wood. Extending the time when the joint is held open can reduce the shrinking and swelling caused by the moisture from glue.

The wetting of the surfaces is a basic necessity for successful gluing. It is not possible to get two surfaces so close that they would stick to each other. Therefore, glue is used to fill the roughness on the surfaces. Good glue fills the majority of the empty spots on the surfaces and pushes away the air that has accumulated in them.

Gluing together woods of different density must be avoided, if the glue joint will be exposed to large variation in humidity. Gluing tangential surfaces together with surfaces cut along the grain can be difficult, for example in a single-notch frontal joint. Therefore, it is advisable to avoid broad structures.

The quality of the surface

In gluing, the most important qualities of wood are flawlessness, smoothness and cleanliness of the wood surface. The best gluing result is achieved with a planed and smooth surface. When polishing, the surface of the wood breaks. This means that the compression pressure must be increased in order for the glue to penetrate the unbroken wood. A surface that is overheated or burned gives a poor gluing result.

Tree species

The gluability of wood is affected by

- the density of the wood.

- the hygroscopic properties.

- the proportion of resin and extracts.

Properties of the most commonly used woods, which should be taken into account in gluing, are gathered in the list below:

- pine and spruce are easy to glue.

- birch swells and shrinks a lot and its surface hardens here and there, in which case the wetting of the surface remains incomplete.

- the grain direction of maple has to be taken into account to prevent warping.

- the resin of larch may hinder phenolic gluing.

- oak and palisander contain tannic acid which may cause joint breakage.

- the acidity of oak and the large tannic acid content of its heartwood may cause blotches with alkaline glues.

- mahogany and walnut tree dye when using alkaline glues.

- the oil content of teak may weaken the adhesion of glue.

The gluing properties of especially tropical tree species differ significantly, and often a separate glue composition has to be developed for each tree species.