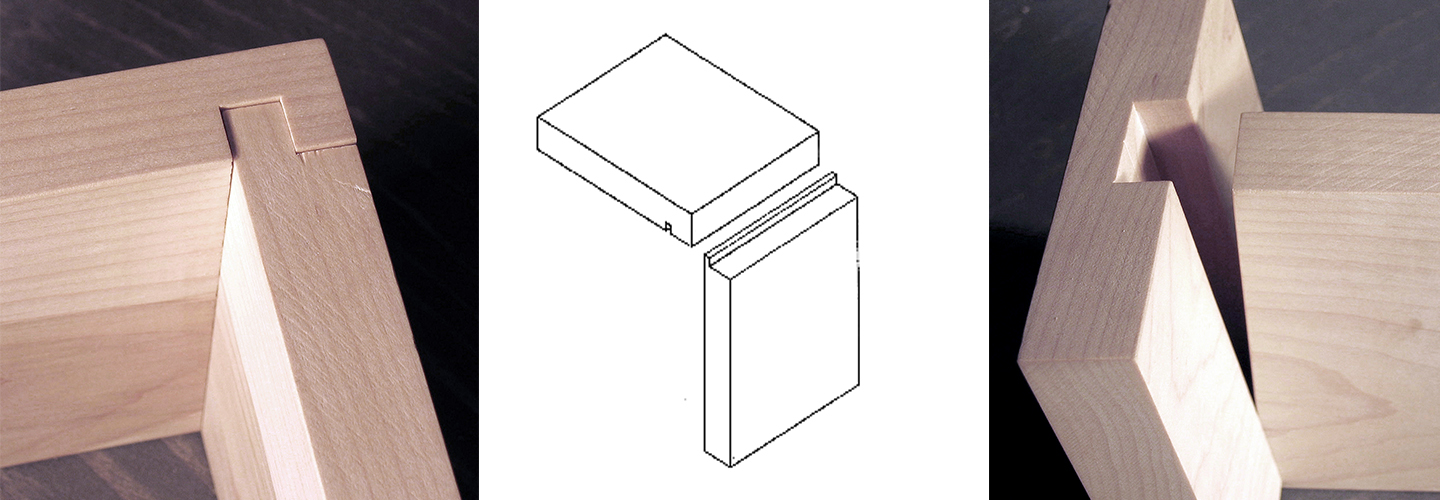

Groove joint is used in corner joints and it can be made across or along grains. It is easy to make but it is quite weak. Visually it looks quite good. Easiest is to make a basic groove joint with one rectangular tenon. If one wants to decrease the amount of cross cut wood in the joint, it can be covered groove joint. Joint can be stronger by designing it as dovetail groove joint.

When it is designed so that moisture movements of both pieces are the same it can be used with broad boards. If it is designed against grains the joint should not be broader than 100 mm.

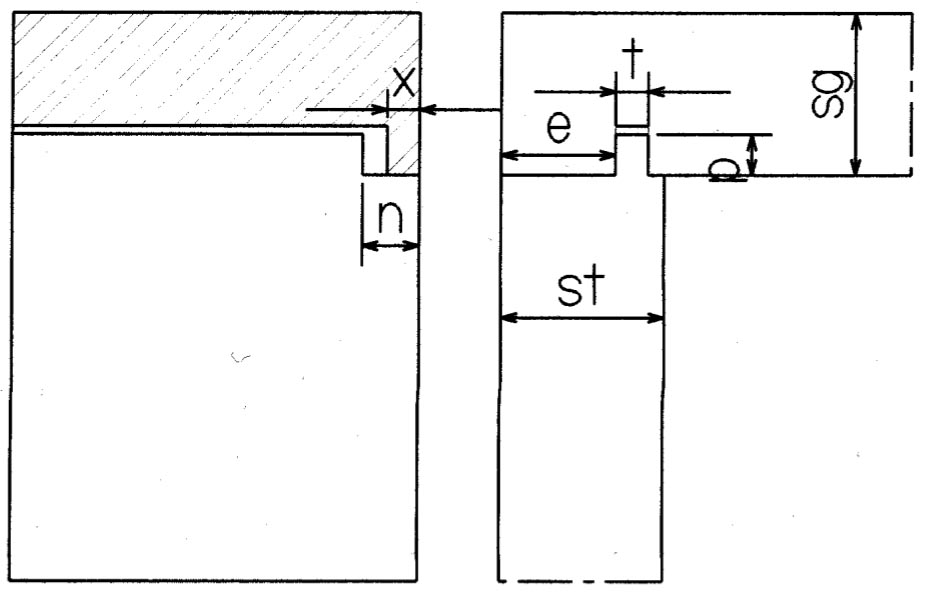

The length of the tenon

The length should be at least 3 mm and maximum ¼ of the thickness of the grooved piece. If the tenon is longer it will make the grooved piece too weak.

The thickness of the tenon

If grooved joint is used in the corner joint the thickness of the tenon should be 1/7 of the dimension e in the picture 2. This is because the groove weakens edge very much. For the same reason the tenon must not be made very tight otherwise it will break the edge. Usually best results with massive wood are achieved when tenon is 0.1 mm thicker than groove.

Notch

If the joint is wanted to be invisible the tenon must have notch . In that case at least 3 mm of edge wood of the grooved piece should be left uncut to make the grooved piece stronger.

Design parameters

Here are basic parameters of groove joints in two different cases. You can see parameter symbols from the picture.

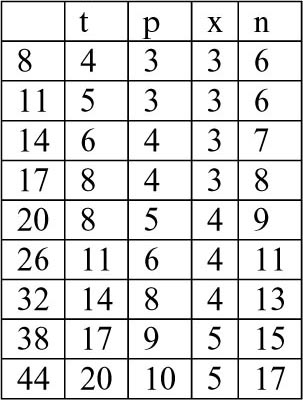

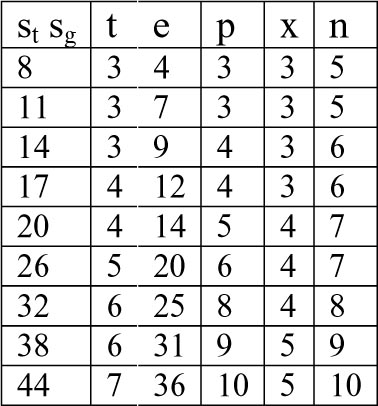

The joint is at the corner

The joint is in the middle of the grooved part