Before lathing or slicing the veneer, the logs are infused until the wood becomes soft. The infusion time varies from a 24 hours to a week, and the temperature between 60-80 °C depending on the tree species.

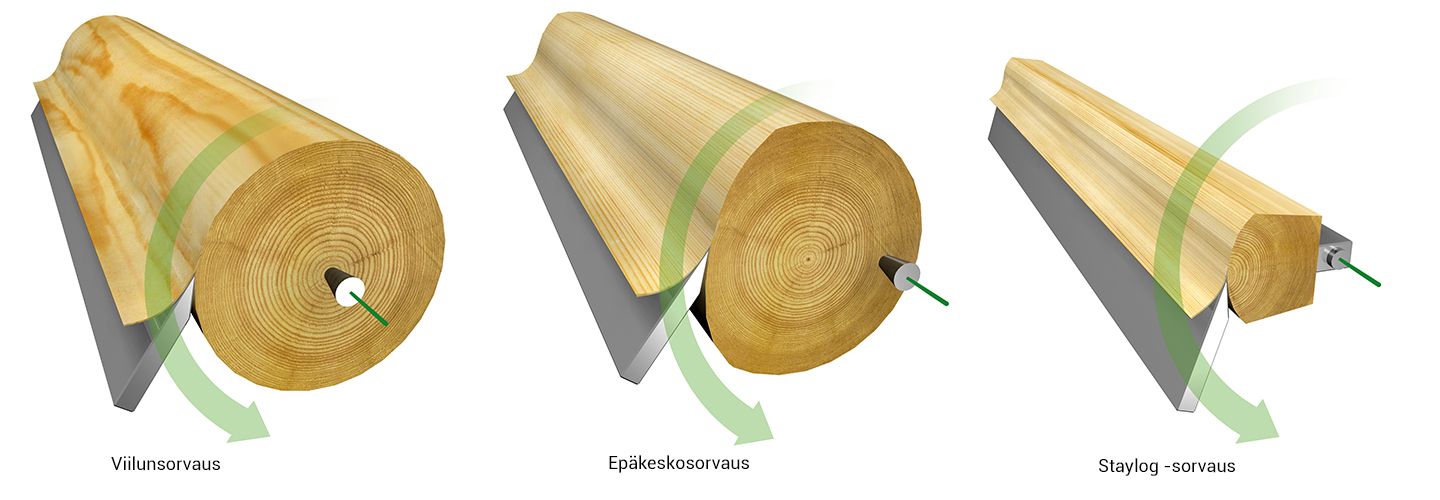

Industrial veneer is produced by lathing or slicing. Generally the cheapest tree species are lathed and the more valuable ones are sliced for veneer that is used for more demanding purposes. The production method affects the surface finishing properties and the appearance of the grain pattern. Carpenters can also produce separate veneer surfaces by sawing.

Production methods for veneer

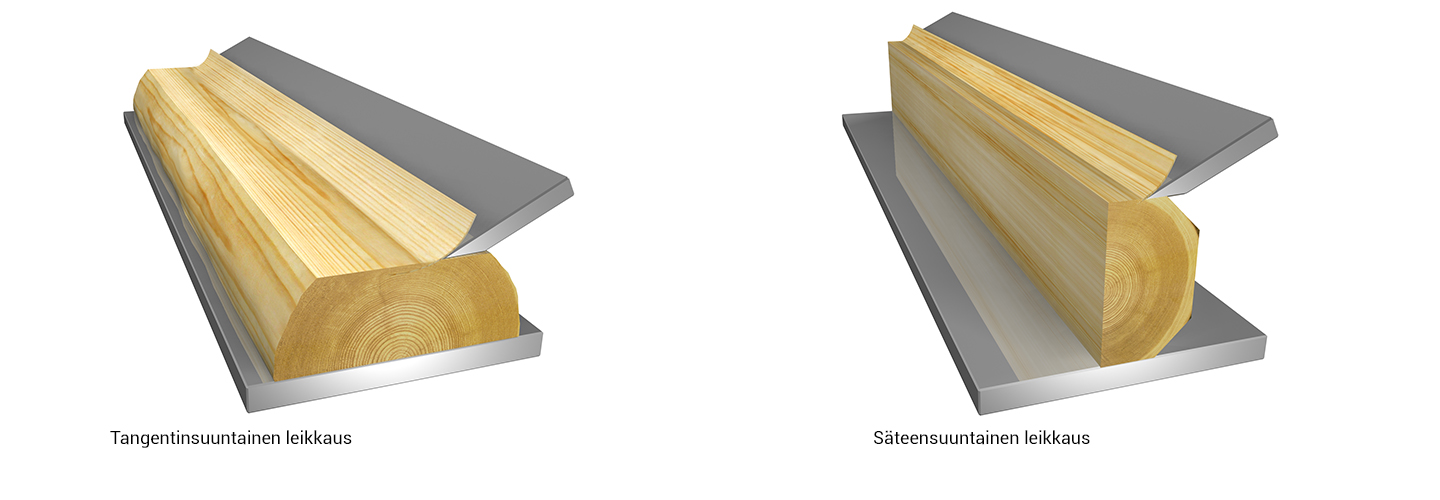

Sliced veneer is produced by lathing veneer chips from the log. This way the grain pattern of the veneer remains natural. Slicing provides thin veneers and the amount of raw material waste stays small. Moreover, no cracks hindering further processing are formed on the surface of the veneer, unlike on lathed veneer. The production of sliced veneer is more expensive than lathed veneer, but its properties are better in many respects.

Veneer sliced from valuable tree species is used as surface material in furniture and upholstery, because sliced veneer is considered to have the most beautiful pattern.

In lathing a block of wood is rotated in a veneer-cutting machine. At the same time a saw blade is pushed against the block. It cuts “veneer mat” from the wood’s surface. When all available wood has been lathed from the block, a thin part from the core of the tree remains. It is called the peeler core or the veneer core.

Lathed and crooked veneers have to be straightened flat, in which cae thin hair cracks appear on the surface of the veneer. As the veneer ages, the cracks along the grain become widen.

Rotary-cut veneer is cheaper and it produces broader veneer leaves than slicing. Rotary-cut veneer is mainly used in plywood production. The most common production methods for veneer are rotary-cut, staylog, flat slicing, quarter slicing and rift-cut

Apart from these methods, different kinds of pyramid, root and clam patter veneers, which are lathed or sliced, for example, according to the cross section of the log or near a branch.

Veneer drying

After lathing or slicing the veneer leaves are dried separately on a drying line. How much time it takes to dry varies between different tree species and the strength of the veneer. If veneer has been dried correctly, it will not crack nor rot, and its workability is the best. The proper percentage of moisture is 8-12 %.

Finishing veneer

After drying, the veneers are finished. They are straightened from the ends and edges, after which they are bundled with string into bunches of 24 or 32 veneers. The bunches are marked, and all veneers from the same log are carefully held together and stored in a monitored and humid space.