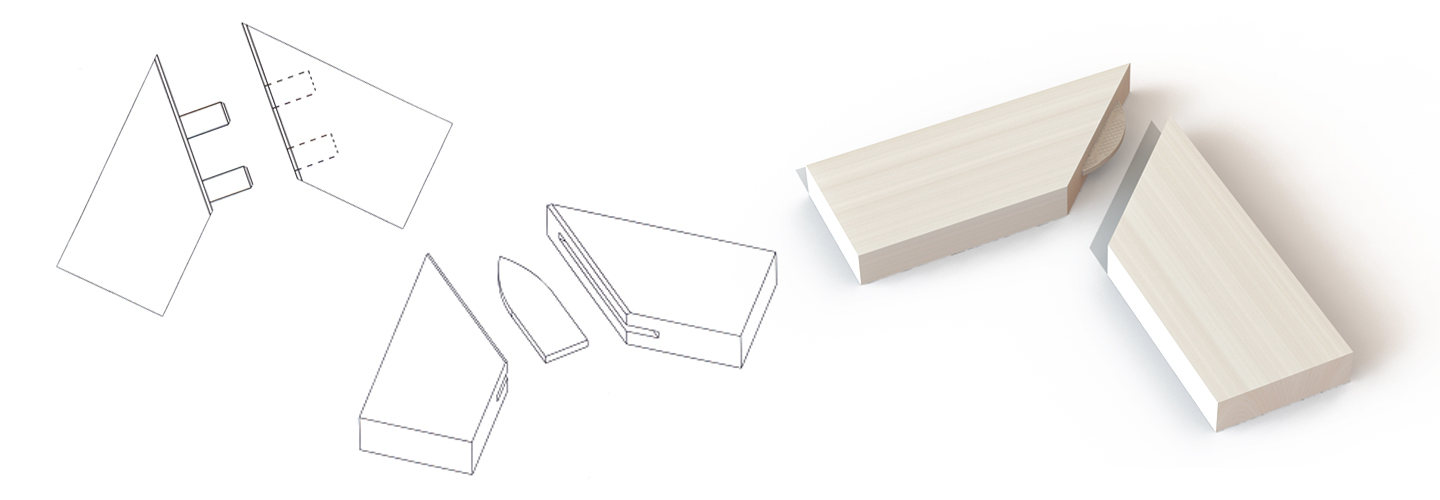

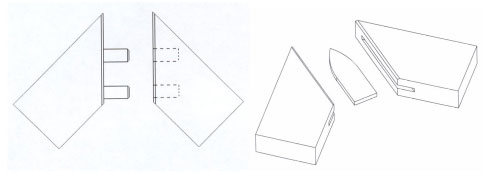

The mitred joint consists of two pieces usually cut in 45o. These pieces can be joined together in different ways. One can use dowels, a cover strip, a lamello joint, or different profiles, for instance a finger joint profile. A mitred joint can also be a combination of these or it is possible to make a slot joint partly mitred.

A mitred joint is good looking because there are no cross-cut surfaces visible. The main problem is that it requires very good machining accuracy. Even minimal deviations from the right cutting angle cause gaps in the joint. To hide these gaps, the joint is in many cases chamfered. The requirement for accuracy grows as the width of the joined pieces grows.

Design

One problem with the mitred joint is that it does not stand moisture variations, especially when the joint is wide. This is caused by the geometry of the pieces. When the piece swells or shrinks it causes the joint to give up. When the joint swells crack arises in the outer corner and when the joint shrinks crack arises in the inner corner.

Calculation example

How big will the crack be in a 100 mm wide frame , when the moisture of wood changes 2% and total swelling and shrinking of wood is 8%.

Hint: the breadth of the crack is √2 * the breadth change of the piece The breadth change is √2 2%/30%*8%*100 mm=0.5 mm

The breadth change is √2 *0.5 mm = 0.75mm

In a corresponding situation the crack arising in a 50 mm wide joint is only 0.38 mm

In practise the joint is bound with glue which decreases cracking. If the pieces are joined with a finger joint, which is very strong, moisture variations can cause a frame with mitred joints to change shape

Machining

The mitred joint can be made with standard machines, but you must be really familiar with them in order to achieve sufficient accuracy. A better method is to use for example an NC router, where the joint can be made with one attachment. The joint can also be machined with a throughfeed tenoning machine, if it has moving working heads.

Benefits and disadvantages of mitred joint

Benefits

- Neat

- No crosscut surfaces visible

- Easy to make in principal

- It is easy join profiled pieces

Disadvantages

- Requires especially good machining accuracy

- Inaccuracy is easy to see