The most common drying method used for lumber in Finland is done at a chamber kiln. The chamber is filled and emptied a batch at a time. The moisture in the chamber is set so low that the lumber is dried by the airflow inside the chamber. The temperature of the air inside the chamber is roughly 50 – 70 °C.

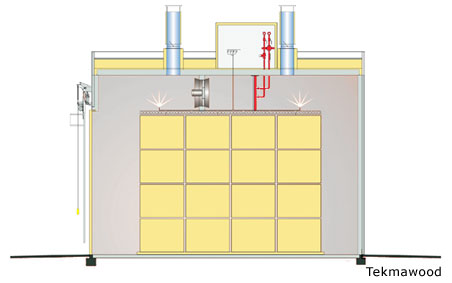

Chamber Kiln

- Fans change their blowing direction automatically

- Radiators

- Ventilation chimneys

- Drying air humidifiers (High-pressure waterspray or steam)

- Sensors for measuring the air temperature and moisture.

- The wood moisture measurement system and drying systemEach wood type and the thickness it’s sawed have their own drying program. Each program has an automated temperature and moisture setting.Drying times depend on the quality goals, wood type and the thickness, the moisture of the wood before and after drying. Typical drying time for a freshly cut wood that has a moisture of 10% will dry from a few days up to a month. The benefits of the chamber kiln are having full control over the drying process.

Properties

- The drying program can be set accordingly for each wood type.

- Wide temperature range 40 – 80 °C

- Good control system

- Readymade presets for drying.

- Suitable for small productions.

- Lumber can be pressurerised for avoiding shape shifts.