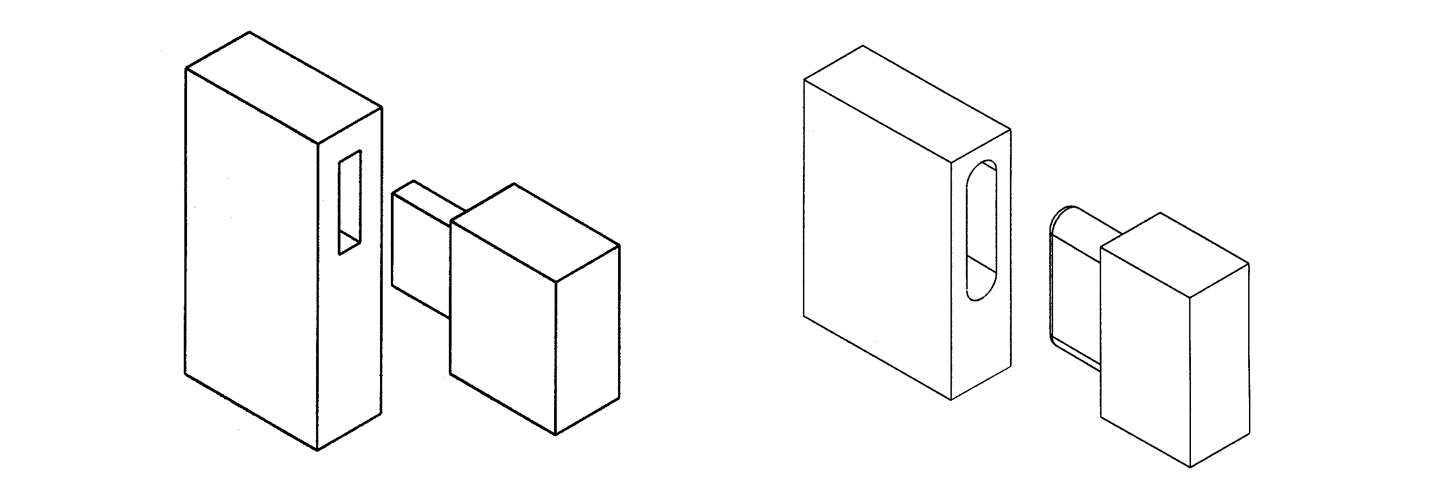

Mortise and tenon joint consists of female mortise in one component and male tenon in the other. It can be made also with two or more tenons. The basic cross section of the tenon is rectangular. This causes also rectangular shape of the mortise which is not always easy to make. Nowadays the shape of the tenon is often oval. Then it is easy to make and it is also a little stronger. The joint is generally very strong.

Strength of the joint

Factors affecting the strength of the joint:

- the strength o the wood

- dimensions of the joint

- the shape of the joint

- glue surfaces of the joint

- tightness of the joint

- glue type

Basic design rules of the joint

Rectangular tenon joint and Oval tenon joint.

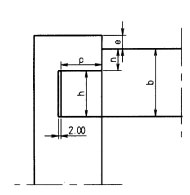

The length of the tenon (p)

The tenon should be made as long as possible to make the joint with maximum tensile strength. However the length of the tenon should not make the mortise too weak. When the joint is in the corner the length of the tenon should not exceed 0.6 * the breadth of the mortise piece. The length of the mortise should be about two millimetres deeper than the tenon.

The dimensions of the joint

The breadth of the tenon (h)

In case of only tension the breadth should be as big as possible. If the joint is in the corner of the structure the breadth of the tenon can be calculated as follows h = 0.6 • b + 0.4 • e.

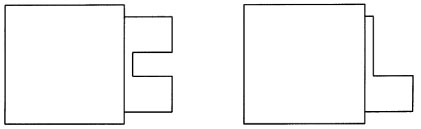

If the breadth of the tenon after calculation is over 100 mm it should be cut narrower like in the picture 4. This is because the moisture movements of the wide tenon would be too big compared to those of the mortise component.

Shape of wide tenons

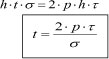

The thickness of the tenon

In case of only tension the thickness of the tenon can be calculated assuming tension force of the tenon equal to the shear force of the surfaces of the tenon as follows.

Cross section of a tenon

where

p = length of the tenon

h = breadth of the tenon

t = thickness of the tenon

τ = shear strength of the glued surface ( 5 N/mm2)

s = tension strength of the wood ( 100 N/mm2)

For instance when applied to the equation we get

![]()

Usually the tenon is made much thicker because there are other forces present. If there is tension the thickness of the tenon should be 1/3 of the thickness of the tenon piece.

Reduction of the width of the tenon (n)

There are two rules for reduction in different cases in pictures below. Condition for these rules is that the length of the tenon is at least as much as it’s width.

n = 0.4 • B + 0.6 • e

n = 0.4 • B

Tapin nakkaus kahdessa eri tapauksessa

The strength of an inclined tenon

Sometimes the tenon must be made inclined. When the direction of the tenon differs from direction of the grain it will weaken the strength of the joint. The strength of an inclined tenon s can be calculated with equation:

![]()

Where sp is tension strength along grains α is the inclination angle

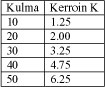

The value of coefficient K is counted in the following table

So the maximum reasonable inclination is about 15o.

How to make inclined tenon stronger? One possibility is to make the tenon thicker. Another possibility is to divide the inclination between tenon and mortise. Also reduction of the length of the tenon increases the strength.

Manufacture of the tenon

Rectangular cross section

If the joint has rectangular cross section it can be made with basic machinery. The tenon can be made with tenoning machine or spindle moulder. If tenon is made with reduction of the width it needs two work phases. Reduction gives more strength to the joint and it covers small defects in the mortise. Cutting of the tenon is made against grains which easily causes tear outs on the side where the tool gets out of the work piece.

The width and thickness of the tenon should always be cutted in one work phase. If it is made with spindle moulder or circular saw in two phases the manufacturing tolerances will be too large.

Oval cross section

If the cross section of the joint has rounded ends it is a little bit stronger but it needs special machinery or an NC-router. The special machine has a cutter which makes a oval movement. It is also possible to make inclined tenons. The dimensions of the tenon can be altered manually or numerically nowadays.

When the joint is used in chairs it must be tilted in one or two directions. If the setting of the machine is made manually it takes a lot of time. Numerical control of the machine makes the setting easier and precise but needs a lot of controlled axes and high investment. Double sided machine needs 11 NC-controlled axes.

Manufacture of the mortise

Rectangular mortise There are two ways to make the mortise.

Chain mortiser is quite effective but the cutting quality is not very good and the cutting tolerance is quite large. One big problem is the roundings of the bottom corners of the mortise. This reduces the length of the mortise or the corners of the tenon must be rounded or chamfered also but this needs an extra work phase.

Boring mortiser has low capacity and large tolerances but the bottom of the mortise is quite even. The tool needs precise setting so that it wont heat and burn. One mortise needs many cuttings and it is slow to work with.

Oval mortise

The oval mortise can be made with deep hole drill or NC-router. The tool oscillates and moves into the wood simultaneously. The tool in this case is quite thin compared to its length and the feed must be done carefully. Basic rule of the feed is that cutting depth must not exceed the diameter of the tool. The cutting quality and the accuracy is quite good.

Tolerances of manufacture

The tenon should be made 0.1 mm thicker than the mortise when manufacturing method has good accuracy. When manufacturing accuracy is lower, the tenon should be 0,2 mm thicker than the mortise. Tolerance also depends on the wood specie used. Soft wood needs tighter joint.

Benefits and disadvantages

- A strong joint if the tenon is long enough

- An oval joint needs special machinery

- The joint needs an extra long component

- A clean joint